ENVIRONMENT

For Westenergy, sustainability means not only managing environmental impacts but also continuously working towards cleaner energy production and a more advanced circular economy.

Westenergy takes a comprehensive approach to environmental responsibility: our operations are based on continuous development, environmental impact management, and promoting the circular economy. We closely monitor our environmental impacts and utilise advanced measurement methods and technologies to ensure that our operations comply with environmental permit requirements.

Our environmental management is based on an ISO 14001-certified system, which guides our operations and development efforts.

Our environmental management follows an ISO 14001-certified system, which directs our activities and continuous improvements. Our environmental program is based on a thorough identification of environmental aspects, and over the past year, we have focused on optimising the consumption of chemicals used in flue gas purification. We are also actively involved in projects that support the development of the circular economy and resource efficiency.

Monitoring air emissions is one of the key aspects of environmental impact assessment.

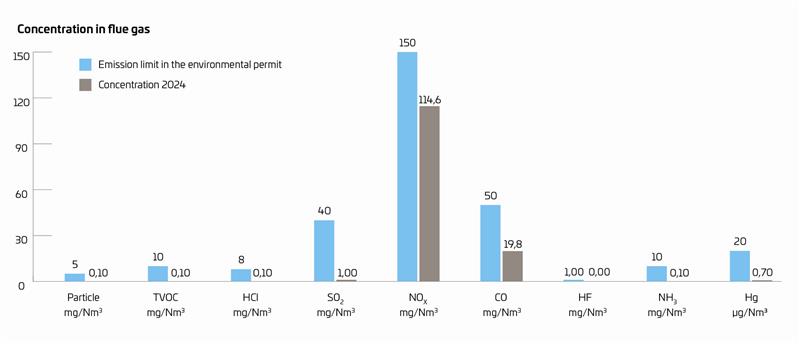

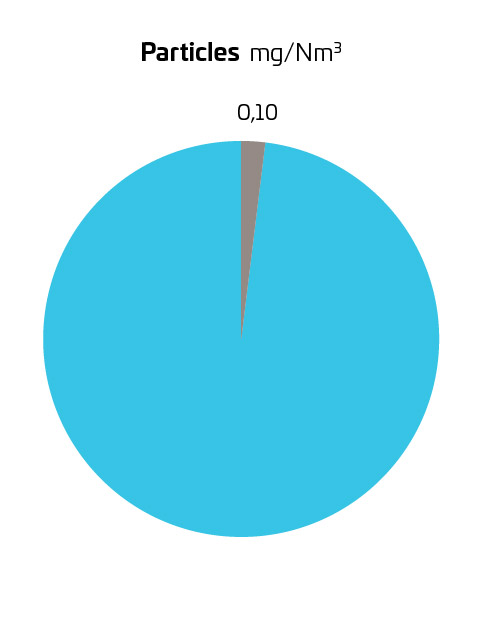

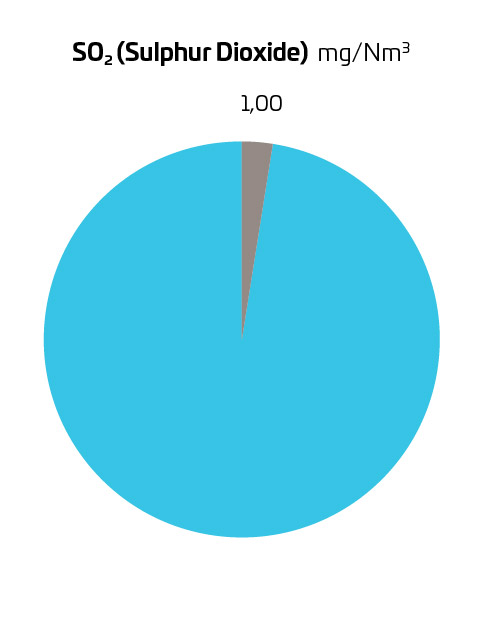

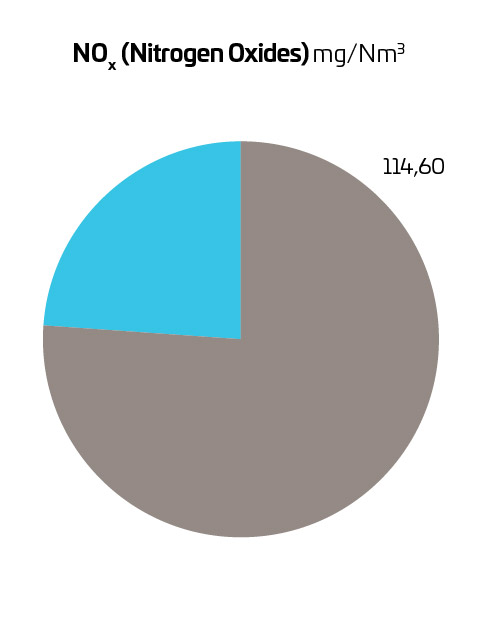

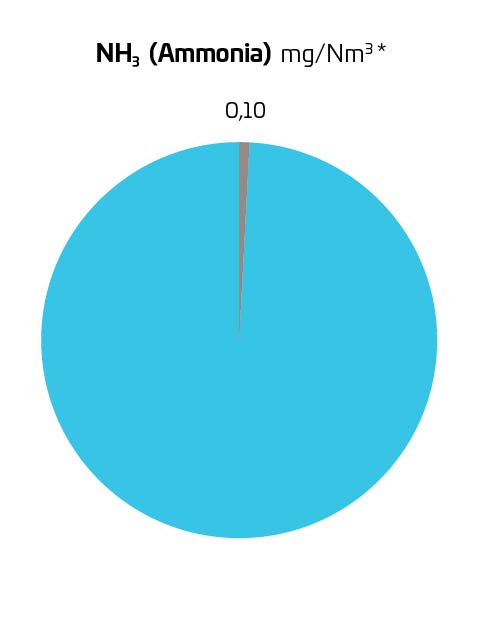

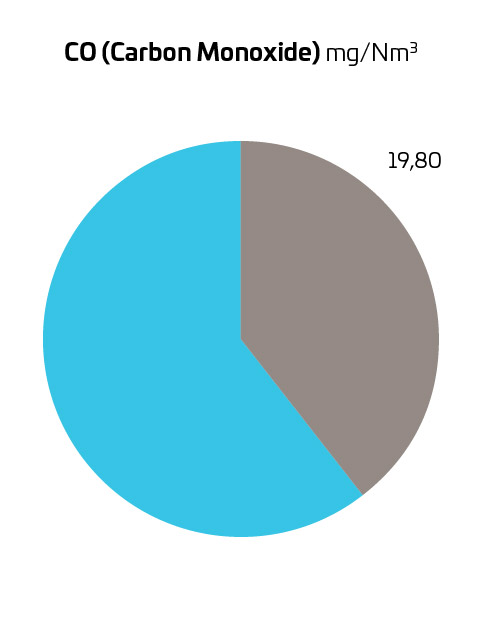

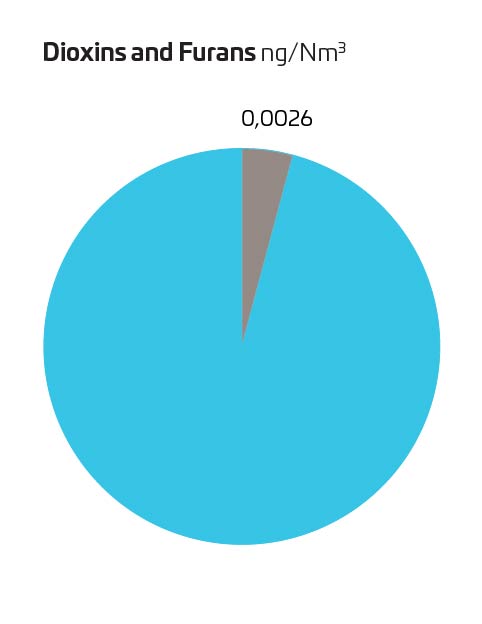

Monitoring air emissions is a crucial part of environmental impact assessment. We conduct continuous air emissions monitoring and report the results regularly to the authorities. The diagram below presents the measurement results for 2024: the full pie chart represents the limit value for a pollutant as defined in the environmental permit, while the grey area inside the circle indicates the actual measured concentration.

The results of the continuous measurements in 2024

As the results indicate, flue gas treatment at Westenergy’s plant is at a high level. The stricter emission limits that came into effect at the end of 2023 guided our operations throughout the entire year for the first time. Our emission values remained well within the new limits, which was made possible particularly by the flue gas scrubber introduced a few years ago. The scrubber effectively removes acidic impurities from flue gases.

The monitoring and reporting of carbon dioxide emissions have also further improved. We have established our practices and prepared for the next steps towards capturing carbon dioxide from flue gases.

Carbon capture and utilisation will significantly reduce our plant’s carbon footprint in the future.

In addition to air emissions, we monitor the consistence of the condensation water formed in the flue gas treatment process as well as the consistence of the surface and groundwater in the area. No significant changes have occurred in the consistence of the condensation water or in the quality of the surface and groundwater during the plant operation.

We have also made significant improvements in water consumption over the past year: condensation water is now utilised more extensively in plant processes, reducing our dependence on external water sources, namely the municipal water supply. This is part of a broader circular economy approach, where water is recycled within the plant while maintaining its excellent quality. The plant’s water purification process functions flawlessly, as confirmed by monthly water sample analyses.

We have also made significant improvements in water consumption over the past year: condensation water is now utilised more extensively in plant processes, reducing our dependence on external water sources, namely the municipal water supply.

We also monitor the condition of vegetation in the vicinity of the plant in collaboration with experts. The status of the kidney lichen (Nephroma bellum), which grows in the Vedahugget conservation area, is regularly observed, and no significant changes have been detected in its occurrence. Additionally, we participate in a bioindicator study that provides broader insights into the effects of air quality on vegetation. Joint air quality monitoring in the Vaasa and Mustasaari regions continues as part of a long-term collaboration.

Going forward, we will continue our systematic efforts to achieve our environmental goals and actively prepare for upcoming regulatory changes. We closely monitor developments in emissions trading and climate policy and proactively adapt to potential changes as part of our environmental program.

Waste quality monitoring

Monitoring waste quality is a key part of environmental permit obligations and the management of Westenergy’s plant’s environmental impact.

From an environmental perspective, waste quality monitoring is essential, as it is a fundamental requirement of environmental permits and plays a crucial role in managing the plant’s environmental impact. Waste is a highly diverse raw material, and its quality affects not only environmental protection measures but also the efficiency of energy production processes. Incorrectly sorted waste fractions can pose challenges to process control, plant operations, and the efficiency of flue gas purification. For this reason, waste quality monitoring is a vital part of the company’s environmental responsibility.

Last year, we monitored a total of 45 waste loads, which corresponded to approximately 1,228 tons of waste.

The environmental permit requires to monitor a minimum of 30 waste loads per year. Last year, we monitored a total of 45 waste loads, which corresponded to approximately 1,228 tons of waste. Waste quality monitoring activities have been carried out at Westenergy since 2013 on a year-round basis, which highlights both their extent and significance.

In the future, waste quality monitoring is planned to be automated alongside manual practices.

Traditionally, waste quality monitoring has been conducted as visual observation. However, the aim is to automate monitoring alongside manual practices in the future. Last year, we focused on the research and development of AI-assisted waste identification and monitoring systems as part of the Ekoälyä project. Automated waste monitoring systems can improve the detection of incorrectly sorted waste, reduce human contact with waste, and thus help mitigate environmental and health risks.

At Westenergy, developing the professional skills of our employees, investing in well-being at work, and maintaining a positive team spirit are of utmost importance.

At Westenergy developing the professional skills of our employees, investing in well-being at work, and maintaining a positive team spirit are of utmost importance. The waste-to-energy sector, technology, and the systems we use are constantly evolving, so our personnel need up-to-date knowledge and skills to meet the ever-changing challenges and opportunities of our field and operating environment.

During annual development discussions, we create a personalised training plan for each employee, considering both the company’s needs and the employees’ own development goals. In 2024, our personnel accumulated a total of 79 training days.

In 2024, our personnel accumulated a total of 79 training days.

Over the past year, we experienced more personnel changes than before. Some of our long-term employees moved on to new challenges, reflecting the high level of professional competence our employees hold in the job market. Conversely, we welcomed new enthusiastic and promising talents to our team. For example, the progress of the carbon capture project and the launch of the Ekoälyä initiative made it possible for us to recruit project-specific roles.

Westenergy hires a significant number of summer workers each year relative to the size of its workforce.

Throughout last year, we employed a total of 44 people. Of these, 32 held permanent positions, while 12 were on fixed-term contracts. Many of the fixed-term employees were summer workers who covered shifts in plant production and helped maintain outdoor areas. In fact, we consistently hire a significant number of summer workers each year relative to the size of our workforce.

Many of our summer workers are students, and we maintain close co-operation with educational institutions, for example through thesis projects. Our waste-to-energy plant is also a popular destination for school visits, and in 2024, nearly 1,000 visitors came to learn about our operations on-site. We also collaborate with educational institutions across the country in many of the circular economy projects we are involved in. Whenever possible, we strive to participate in other collaboration projects with educational institutions. Last year, for example, we partnered with the Junior Chamber of Commerce in Vaasa on the Värityskirja project, which introduced children to future career opportunities in the Vaasa region.

Collaboration with educational institutions supports the development of our employees’ skills as well as the growth of new talent in the industry.

Collaboration with educational institutions supports the development of our employees’ skills as well as the growth of new talent in the industry. Thesis projects and joint initiatives provide opportunities for both students and Westenergy’s experts to share and deepen their knowledge. In addition, active collaboration with schools helps us reach potential future employees and enhance the attractiveness of the waste-to-energy sector.

Our occupational well-being enquiry showed that employee satisfaction is at a high level within our organisation. Over the past year, we invested in our employees’ well-being in various ways, including organising several events to promote workplace well-being and team spirit.

At the turn of the year 2023–2024, we conducted an occupational well-being enquiry for our employees, which included a survey, personal interviews, and occasions for different employee groups for reviewing the results. Overall, the survey showed that employee satisfaction is at a high level within our organisation. Over the past year, we invested in our employees’ well-being in various ways, including organising several events to promote workplace well-being and team spirit. In the spring, we organised an ice hockey event at Vaasan Sähkö Arena, and in the fall, employees got to explore Vaasa’s mysterious history through a ghost walk. We also held a summer party, and the holiday season was celebrated traditionally with our owner companies. Additionally, our employees have access to a well-equipped gym to support their overall well-being.

Our occupational safety goal is to ensure a safe working environment for both our employees and external partners operating within our plant area. Through our operations, we continuously strive to prevent workplace accidents and health hazards while improving working conditions and the overall work environment.

In 2024, we invested purposefully in the development of occupational safety. Maintaining a high level of safety has been a significant, positive, and shared challenge for our entire organisation.

Maintaining a high level of safety has been a significant, positive, and shared challenge for our entire organisation.

Safety observations are an important tool for anticipating potential hazards among our employees. Every safety observation is reviewed daily, and we strive to carefully identify the underlying causes to implement the necessary improvements for maintaining safety. In 2024, our employees reported a total of 59 safety observations. Reporting was also improved and made more accessible by introducing anonymous paper forms alongside digital systems.

At Westenergy, it is also essential that all employees have up-to-date first aid training and a valid occupational safety card. Additionally, safety awareness is enhanced through safety briefings, where current safety-related topics are discussed. In 2024, we organised a total of 26 safety briefings, which is a significant increase compared to 18 briefings in the previous year. Topics covered in these briefings included fire safety procedures for the feed hopper, the use of compressed air equipment, and enhancing the monitoring of the intermediate storage area.

In 2024, we organised a total of 26 safety briefings, which is a significant increase compared to 18 briefings in the previous year.

Westenergy’s health and safety committee gathered four times during the year to address safety observations and areas for improvement. Employees conducted four safety inspections at the plant site, where issues were resolved on the spot when possible, and necessary actions were escalated to the health and safety committee. Additionally, the committee monitored the implementation of the occupational safety program and continued its close collaboration with occupational health services, as in previous years.

During the annual maintenance service stop in the spring of 2024, a total of 120 people worked simultaneously at the plant. This large number of external personnel working in different parts of the facility makes annual service stop particularly critical from a safety perspective. Clear guidelines, comprehensive safety training, and excellent cooperation with Rescue Team Finland Oy in safety supervision ensured that the maintenance work was carried out smoothly and without any workplace accidents.

Overall, one workplace accident leading to sick leave was reported last year, breaking the company’s long streak of being accident-free. The incident was thoroughly investigated, and the lessons learned were applied to prevent future risks. In 2025, the safety target is once again to maintain a zero-accident workplace.

In addition, the safety goals for 2025 focus on improving both systems and operating procedures. Plans include implementing a new access control system and a risk management program to streamline and enhance safety efforts. For personnel, the emphasis will be on clearer task allocation and shared responsibility for safety within the organisation. Security in area monitoring will also be further enhanced. Looking ahead, the carbon capture project is expected to bring new safety challenges that require careful preparation.

The goals for 2025 include the implementation of a new access control and risk management system, clearer allocation of safety responsibilities, and enhanced security in area monitoring.

Overall, the separation of safety management into its own role in 2023 has enhanced safety oversight over the past year. Now, all safety-related matters are directed to the H&S Engineer, streamlining decision-making and task delegation. This creates a strong foundation for the long-term development of safety in the future.